In fact, the author thinks that many additives are still ok, some are pure natural, such as our equipment manufactured for feeding plants, people use natural, all exports, domestic products are rarely seen by them !

The selected pulverizer is slightly greater than the actual production capacity, and when the production capacity of the pulverizer is reduced by the wear and leakage of the hammer, the continuous production supply of the feed is not affected. After the airflow pulverizer is filtered, the pulverizing cavity is sprayed through the Raval nozzle, and the material is repeatedly collided, friction, shear and pulverized, and pulverized material in the intersection of the multi-shaped high-pressure airflow. Next, the rising airflow is moved to the hierarchical region, and the crude material is separated under the powerful centrifugal force generated by the high-speed rotation, the fine particles that meet the particle size requirements are collected by the grading wheel into the cyclone and the dust collector, and the crude particles drops to the pulverization. The district continues to smash. Ultrafine pulverizer is low, and all of the lifescas is used in high quality wear-resistant materials at home and abroad. It has long service life. A small amount of easy wear parts are made of special hard resistance, small size, light weight, easy to replace the accessories. The ultrafine pulverizer is composed of silo, mechanical pulverizer, air blower, cyclone, vibrating screen, liquid nitrogen tank, etc., the deep-cooling pulverizer system is refined by liquid nitrogen as a cold source, and it is crushing at low temperatures by cooling. After the crushing state, enter the mechanical pulverizing cavity through the impeller high speed rotation, the material and the blade, the tooth disc, the material and the material are enrolled under the integrated effect of collision, shear, friction, etc., to achieve a crushing effect.

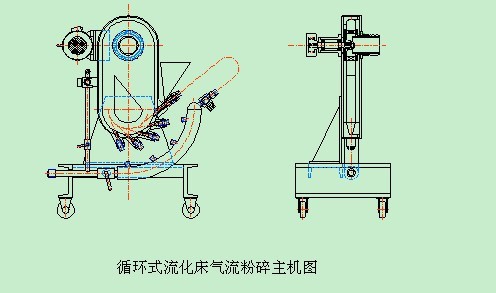

SF-300 high speed gas flow grinding is a crushing device. For us, it is also the object we study. So let's briefly introduce this crusher. I hope that you can understand other types of crushers while understanding the airflow crusher.

In order to adapt to information technology, biotechnology and new material technology for higher requirements of powder product particle size, purity and particle size distribution, superfine gas flow crushing technology should improve and optimize ultrafine gas flow crushing equipment, develop new equipment, pay attention Matching design of crushing and classification system.

Apartum method: According to the material, the pharmaceutical factory can select the high-speed mixer model according to the model selected by the peer vendor. The advantage of this method is convenient and simple, and the choice is small, and there is less error. However, the first condition is to grasp the imperfein of others. This is very difficult. Once the error is encountered, choose will detourRow.

Since the high-speed mixing machine amplification coefficient data is rarely announced, the monogram should be closely fitted with the equipment factory, pay attention to stirring uniformity, power change, stirring time, and stir start. The reliability of further selection is guaranteed only when the test results are consistent with the proposal results.

In July 1996, the National Power Industry Dust Control Conference requested that the grain concentration of the workplace has reached more than 90% in 2 years from 1996, and the posture floor dust concentration has a qualified rate of more than 90%.

Because the Raval nozzle is mounted at an acute angle, the high-speed jet is circulated with the animal material in the pulverized chamber, and the particles hit, collide, rub and pulverize each other with the particles and the fixed target wall surface.

In general, the order of the charm is: blocking the selection machine returning slot - stopping the water supply - Once the ore in the tank is all discharged, press the stop button - the mineral spiral portion.

Due to the manufacturing error and characteristic error of the motor, the power is unbalanced. Once the power of a motor is too large, it will cause burning car accidents. Therefore, the power balance between the motor should be controlled to improve the balance accuracy.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line