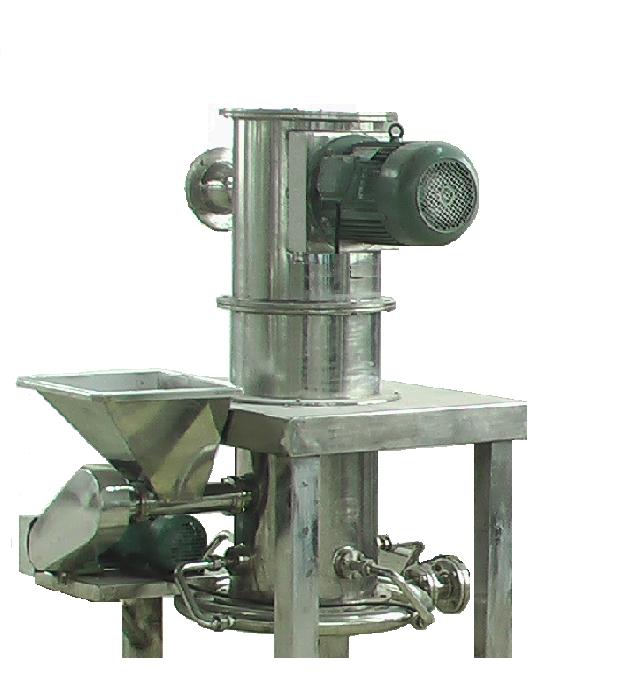

Today, I will talk about the maintenance and maintenance of the gas flow grinder. After the airflow pulverizer is filtered, the pulverizing cavity is sprayed through the Raval nozzle, and the material is repeatedly collided, friction, shear and pulverized, and pulverized material in the intersection of the multi-shaped high-pressure airflow. Next, the rising airflow is moved to the hierarchical region, and the crude material is separated under the powerful centrifugal force generated by the high-speed rotation, the fine particles that meet the particle size requirements are collected by the grading wheel into the cyclone and the dust collector, and the crude particles drops to the pulverization. The district continues to smash. The ultrafine pulverizer is composed of silo, mechanical pulverizer, air blower, cyclone, vibrating screen, liquid nitrogen tank, etc., the deep-cooling pulverizer system is refined by liquid nitrogen as a cold source, and it is crushing at low temperatures by cooling. After the crushing state, enter the mechanical pulverizing cavity through the impeller high speed rotation, the material and the blade, the tooth disc, the material and the material are enrolled under the integrated effect of collision, shear, friction, etc., to achieve a crushing effect. Ultrafine pulverizer is low, and all of the lifescas is used in high quality wear-resistant materials at home and abroad. It has long service life. A small amount of easy wear parts are made of special hard resistance, small size, light weight, easy to replace the accessories. The following is the maintenance and maintenance items of gas flow mills.

Airflow pulverizer is a machine that can be deformable and divided into smaller particles. At present, the airflow pulverizer has been widely used in a variety of industries. Given that the airflow pulverizer is the basic processing technology in the production and application of Chinese medicine, ultrafine pulverization has caused more and more attention. Although it starts late, the variety is relatively small, but its unique advantage and broad application prospects. The working principle of the pulverizer is different, so the development of the pulverizer also shows the development of diversification. The increase in this type will inevitably lead to the emergence of various problems. The principle of several types of crushers in the market below and how Solve these issues and daily maintenance and repair have made a brief introduction! At present, there are a large number of grinders on the market, not only can reduce the green vines in the feed, but also high stalks, but also smash sweet potatoes, corn, usually used in rural machinery. As the service time is prolonged, the following faults often occur: no power during crushing; not started; not electricity. In general, you can repair themselves. First, check if the power outlet, plug, power cord is oxygen-off, disconnect (as) can be inserted into the power testing machine, the motor power is not rotated, gently knocking the car wheel, can conclude: two starts of the machine One of the capacitors is faultycaused. In this case, there is usually only a new product. In another case, the power is not rotated, the external force can be rotated, but there is a weak current noise in the motor, which is due to the slight leakage of the starting capacitor. If the current is too loud, the motor does not start at all, the conclusion is that the start capacitor short circuit is caused (the motor coil is short-circuit requires professional maintenance). In the absence of a professional instrument, the capacitor can be removed, inserting the two leads into zero and fire line jacks, charging the capacitance, and then removes the short circuit discharge of the two wires. If you can emit discharge sparks at this time, you can use a capacitance; if sparks and noise are weak, the capacity of capacitors has been reduced and new or small capacitors are required. If the capacitance is damaged and the circuit is short, the method is not used, and the same specifications must be replaced and repaired. Another category is a small high-speed grinder. The general quality of this pulverizer is not easily damaged. Everyday maintenance is more important, the following is the maintenance focus of this crusher. Check the lubrication of the bearing and check if all fasteners are tight. Check if the transmission belt is installed correctly, the condition is good. If the belt is found, it should be replaced in time. When there is oil in the belt or groove, a clean rag should be used in time. Check if the protection device is intact. If the protection device is found, it should be eliminated in time. Check the material or other debris in the damaged cavity, sometimes remove it. Check if the head or lift rod of the hydraulic hoist is returned, adjust whether the gasket is installed correctly and press.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line