Today, the chat wind grinding effect is remarkable, and below will introduce you to the wind grinding and grinding effect. Ultrafine pulverizer is low, and all of the lifescas is used in high quality wear-resistant materials at home and abroad. It has long service life. A small amount of easy wear parts are made of special hard resistance, small size, light weight, easy to replace the accessories. The ultrafine pulverizer is composed of silo, mechanical pulverizer, air blower, cyclone, vibrating screen, liquid nitrogen tank, etc., the deep-cooling pulverizer system is refined by liquid nitrogen as a cold source, and it is crushing at low temperatures by cooling. After the crushing state, enter the mechanical pulverizing cavity through the impeller high speed rotation, the material and the blade, the tooth disc, the material and the material are enrolled under the integrated effect of collision, shear, friction, etc., to achieve a crushing effect. After the airflow pulverizer is filtered, the pulverizing cavity is sprayed through the Raval nozzle, and the material is repeatedly collided, friction, shear and pulverized, and pulverized material in the intersection of the multi-shaped high-pressure airflow. Next, the rising airflow is moved to the hierarchical region, and the crude material is separated under the powerful centrifugal force generated by the high-speed rotation, the fine particles that meet the particle size requirements are collected by the grading wheel into the cyclone and the dust collector, and the crude particles drops to the pulverization. The district continues to smash.

Good crushing effect can be said to be the most obvious advantage of airflow pulverizer, but at the same time, the shortcomings such as high cost, high energy consumption, and wear equipment have been a well-known gas flow pulverizer that cannot be the shortcomings of mainstream crushers. In recent years, with the continuous improvement of industry technology, the quality and performance of the product have significantly improved, and the market is optimistic.

At present, the main goal of the development of the world's broken industry is to increase fineness, increase production, expand application scope, such as development and application of materials such as fibers, hardness, toughness, viscosity. Elastic, low temperature pulverizer, gas pulverizer is also the focus of many foreign manufacturers.

In general, the airflow pulverization can make the product very fine compared to ordinary mechanical ultrafine pulverization, and the particle size distribution is narrow, that is, the particle size is more uniform. Since the gas expands cooling at the nozzle, there is no heat related to the crushing process, so the cold temperature rise is very low. This feature is important to low melting point and the ultrafine mills of thermal sensitive materials.

There are several airflow grinding machines used in my country: a flat air mill, a fluidized bed shrouding mill, a circulating tubular air mill, a radio gas flow mill and a target gas flow mill. These types of airflow grinding machines are widely used in flat gas flow grinding, fluidized bedsGas flow mill and circulating tube airflow pulverizer.

However, when the airflow pulverizer is pulverized, especially when high-strength materials, there is a problem of high energy and severe equipment wear. The main crushed machinery producing countries in the world mainly include Japan and Germany. Only in Japan, there are hundreds of crusher plants. Yield has reached an amazing quantity, the product packaging capacity is large, wide application range, and technical advantages cannot be comparable. It has been in the leading position in researching and developing airflow crushers. This has brought tremendous pressure to domestic companies. In recent years, with the continuous improvement of domestic industrial manufacturing, the production technology of gas flow crushers has made great progress, basically be the leading market leading, and the industrial development prospects are broad.

Welcome, the above about the air grinding machine is significant.

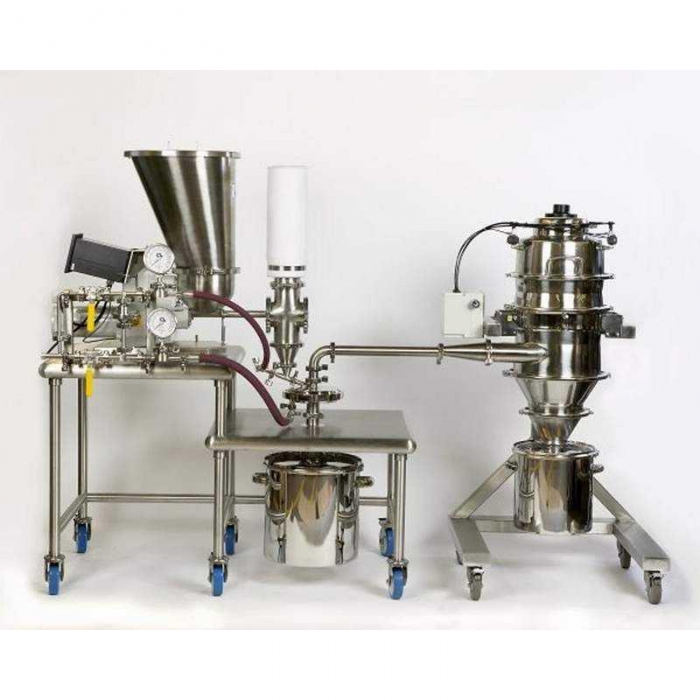

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line