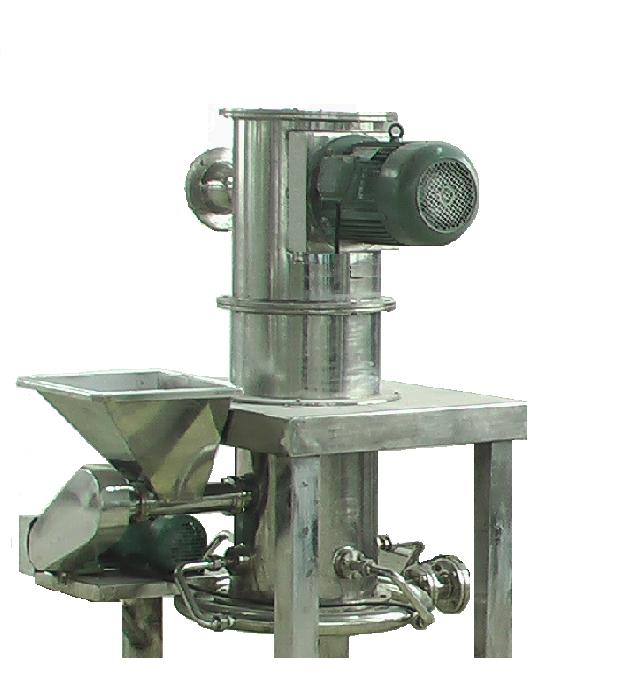

Today, we will discuss the working principle of gas flow grinding machines. Ultrafine pulverizer is low, and all of the lifescas is used in high quality wear-resistant materials at home and abroad. It has long service life. A small amount of easy wear parts are made of special hard resistance, small size, light weight, easy to replace the accessories. After the airflow pulverizer is filtered, the pulverizing cavity is sprayed through the Raval nozzle, and the material is repeatedly collided, friction, shear and pulverized, and pulverized material in the intersection of the multi-shaped high-pressure airflow. Next, the rising airflow is moved to the hierarchical region, and the crude material is separated under the powerful centrifugal force generated by the high-speed rotation, the fine particles that meet the particle size requirements are collected by the grading wheel into the cyclone and the dust collector, and the crude particles drops to the pulverization. The district continues to smash. The ultrafine pulverizer is composed of silo, mechanical pulverizer, air blower, cyclone, vibrating screen, liquid nitrogen tank, etc., the deep-cooling pulverizer system is refined by liquid nitrogen as a cold source, and it is crushing at low temperatures by cooling. After the crushing state, enter the mechanical pulverizing cavity through the impeller high speed rotation, the material and the blade, the tooth disc, the material and the material are enrolled under the integrated effect of collision, shear, friction, etc., to achieve a crushing effect. The following is a brief introduction to the working principle of the gas flow grinder.

The laboratory airflow pulverizer is designed and transformed with advanced technology at home and abroad. It is designed to break ultra-small and high value materials in the laboratory. The machine is made of high quality stainless steel. The pulverizer is divided into horizontal and vertical. The inner lining is made of corundum ceramics. It is very convenient to disassemble, installation and clean. Users can often replace various crushing materials.

The last version made a detailed explanation of the working principle of gas flow grinding, so this knowledge point will not be repeated (unknown children's shoes can be reviewed: the principle of gas flow), but to say that some have not mentioned before Things, such as maintaining its parts, in order to make your child more easily understand the principle of gas flow grinding. We can have more understanding of the airflow pulverizer, master more content, so that we can fully, specific, meticulous, and will not miss any knowledge points. Then, the following version doesn't say nonsense, to expand the specific content. The maintenance of the airflow pulverizer includes: (1) Airfine A. The dust inside the fan should be cleaned once a week, especially the leaves, because dust is most likely to accumulate. b. Bearing boxes are filled with lubricants per month. 2 cophenium sodium product grease is generally used. c. When the fan is started, if you are runningThe fuselage has an abnormality or vibration, and should be closed immediately. (2) Host A, hierarchical impeller, screw feeder, crushing nozzle, etc., mainly checking the wear situation and whether it needs to be replaced. b. Once the mill is running for a while, some parts should be cleaned to avoid affecting the crushing effect of the mill, such as nozzles, grinding chambers, filter bags, etc. c. Bearings should be lubricated as needed, such as grease, but it is not too large to avoid abnormal bearing temperatures. (3) Planetary unloading valve A. If there is any abnormality, it should be closed immediately. b. Clean an impeller and inner position every three months. c. Add grease in a whole three months to lubricate once.

Welcome to buy, the above and mill equipment manufacturers discuss the working principle of the gas current pulverizer.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line