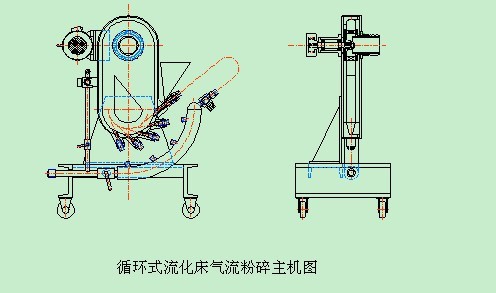

Today, we will discuss the installation method of airflow pulverizer equipment. After the airflow pulverizer is filtered, the pulverizing cavity is sprayed through the Raval nozzle, and the material is repeatedly collided, friction, shear and pulverized, and pulverized material in the intersection of the multi-shaped high-pressure airflow. Next, the rising airflow is moved to the hierarchical region, and the crude material is separated under the powerful centrifugal force generated by the high-speed rotation, the fine particles that meet the particle size requirements are collected by the grading wheel into the cyclone and the dust collector, and the crude particles drops to the pulverization. The district continues to smash. The ultrafine pulverizer is composed of silo, mechanical pulverizer, air blower, cyclone, vibrating screen, liquid nitrogen tank, etc., the deep-cooling pulverizer system is refined by liquid nitrogen as a cold source, and it is crushing at low temperatures by cooling. After the crushing state, enter the mechanical pulverizing cavity through the impeller high speed rotation, the material and the blade, the tooth disc, the material and the material are enrolled under the integrated effect of collision, shear, friction, etc., to achieve a crushing effect. Ultrafine pulverizer is low, and all of the lifescas is used in high quality wear-resistant materials at home and abroad. It has long service life. A small amount of easy wear parts are made of special hard resistance, small size, light weight, easy to replace the accessories. The installation method of the airflow pulverizer equipment is introduced.

The pulverizer cannot be separated from a wide range of crushing equipment, so small Obian believes that we all understand various crushers, namely website products, and we can understand the overall equipment, and can also help us. Learning in our products, it can also increase our knowledge in this regard, which is beneficial to us. We should take seriously. Broken equipment typically includes two mechanical equipment, pulverizing machinery and grinding machinery, wherein the grinding machine can also be referred to as a pulverized machine. Its action is to smash the solid material, convert it into a fine powder or powder material, widely used. Prepare the preparation prior to installation according to the use of the use and some drawings, to determine the process, etc. It should be appropriate. (2) There should be sufficient space around the crushing equipment to carry out feed and maintenance. (3) The base basis should be solid, must have sufficient strength to make the installation of the host and the motor. 2. When the crushing device (1) is installed, the general crushing device does not need to perform a balance test during installation, as its product has been carried out before the factory. (2) The necessary inspections should be performed before the equipment installation. If there is any problem, it should be handled in time. (3) Check the equipment wiring, etc.Check if the direction of rotation of the motor is correct. (4) Install as required. Manually drive the rotor to check if its rotation is flexible.

Welcomes the installation method of the above airflow pulverization equipment.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line